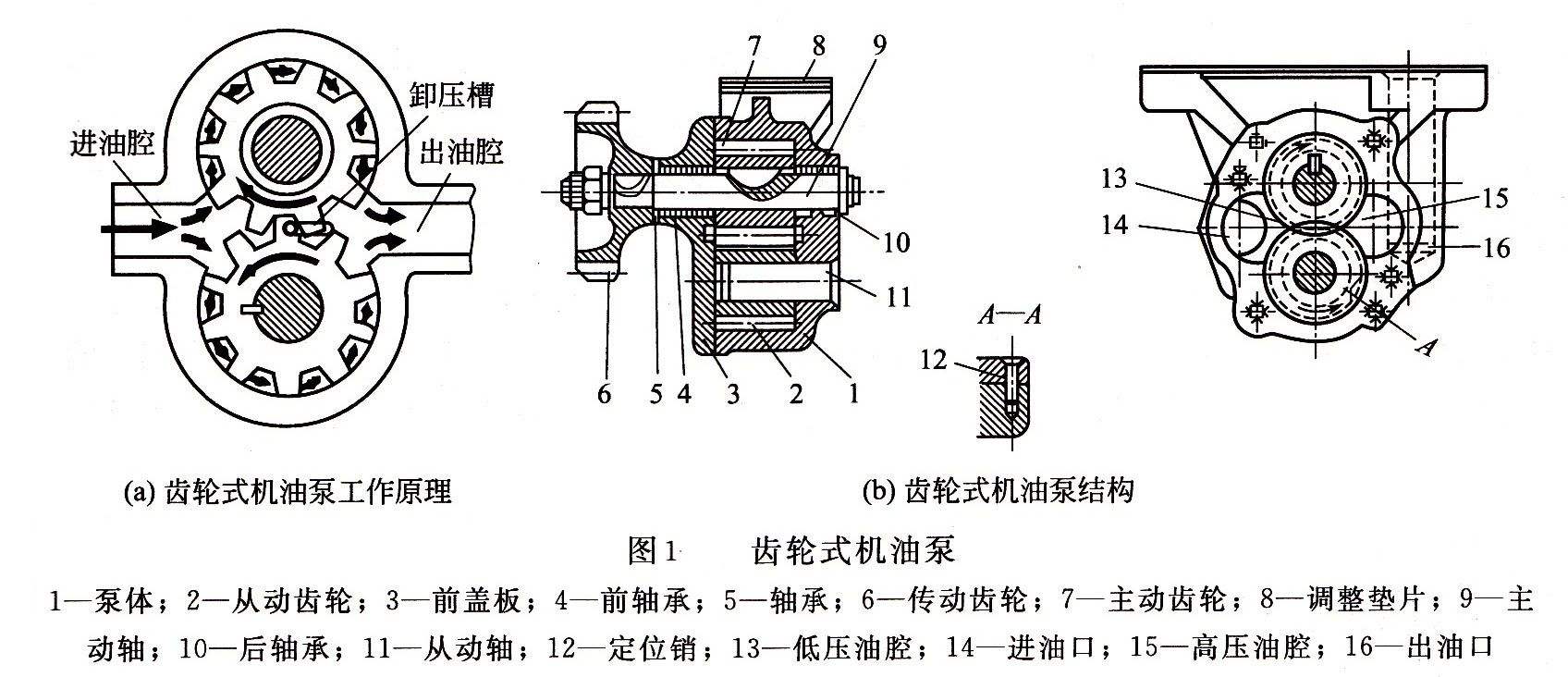

Geared oil pump working principle

When the diesel engine is running, the crankshaft gear rotates through the intermediate gear section of the motive oil pump transmission gear, and the driving gear installed inside the oil pump rotates with the driving shaft, and simultaneously drives the driven gear to rotate in the opposite direction. The driving gear meshes with the teeth of the driven gear to separate the inside of the pump body into two separate sealed spaces. As the gear rotates at a high speed, the oil at the oil outlet between the gear teeth is brought to the pressure oil chamber, so that the oil at the oil pressure chamber is continuously increased, the pressure is increased and the pressure is sent out from the oil outlet. The oil in the suction chamber is taken away, creating a partial vacuum, and the oil in the oil sump is continuously sucked into the suction chamber. The oil pressure of the oil pump is generally controlled by a pressure limiting valve on the oil filter. If the oil pressure is too high, the pressure limiting valve is opened, and the oil inlet port allows the oil to flow directly into the oil sump to prevent pressure in the oil circuit. Excessively high and the oil pump has failed.

Gear type oil pump is prone to failure

Under normal conditions, the oil pump has a relatively good lubrication condition and various wear speeds are relatively slow. However, after long-term use, the gear end clearance and the tooth surface, the journal and the bearing hole, the pump body and the inner wall of the pump casing will also have different degrees of wear. As the wear increases, the various matching clearances increase, and the wear amount reaches When the limit is reached, the oil supply is reduced and the oil supply pressure is lowered.

Inspection method of gear type oil pump

If the diesel engine is found to have insufficient oil supply in the lubrication system, the oil pressure is too low, or the abnormal sound is heard during operation, the following aspects should be checked:

1 Check the viscosity of the oil.

2 Check if the oil copper pipe between the rocker arms is broken and check the position.

3 Adjust the oil pressure. If the oil pressure does not rise during the adjustment process, check other aspects.

4 Check the oil pipeline and joints for oil leakage. If there is no oil leakage, other aspects should be checked.

5 Check if there is any blockage in the oil filter screen of the oil suction pan. In the case that no faults are found after all inspections, the oil pump is disassembled and repaired.

XIAMEN AOT ELECTRONICS TECHNOLOGY CO.,LTD which has 15 years experience in diesel generator spare parts manufacturing. We provide full kinds of generator spare parts for engine replacement and other related electric products such as automatic transfer switch, electric Relay etc. Welcome to contact us for more information.

Contact: Ms.Lika (Sales)

Email / Skype: sales@aotchina.com

Phone/WhatsApp/ Wechat: 0086 15980808150

Web: www.aotchina.com

Contact: Jack

Phone: 0086-19906045242

Tel: 0086-592-7161550

Email: sales@aotchina.com

Add: No.21 Yufu Road, Jimei Disctrict, Xiamen City, China 361000